S E R V I C I N G

DIY servicing - DIY replace pinch roller - DIY demagnetizing - don't do this - professional servicing - rubber parts - upgrade - manuals

At

first don't worry: professional

or high quality reel to reel recorders in

domestic use are

strong enough to maintain constant performances over years.

You can

do by yourself the ordinary servicing: it is more simple than the

right alignment of a turntable arm i.e. !

A tape recorder needs full servicing and alignment after some years of domestic use only. On the other way servicing is done at periodical deadline (as for the cars) and before every important master recording in professional use.

A tape recorder needs full servicing and alignment after some years of domestic use only. On the other way servicing is done at periodical deadline (as for the cars) and before every important master recording in professional use.

WHAT

YOU CAN DO BY YOURSELF.

Periodical cleaning of

every surface in contact with the magnetic tape: heads, tape guides,

capstan shaft and rubber pinch roller. Reel to reel

recorder performances decrease dramatically when too much dust

and

oxide deposits are on these surfaces.S A F E T Y I

N F O R M A T I O N : BEFORE CLEANING

AND/OR SERVICING TURN OFF YOUR OPEN REEL RECORDER AND UNPLUG THE MAINS

CABLE TO AVOID INJURIES TO YOUR HEALTH AND DAMAGES TO THE

RECORDER.

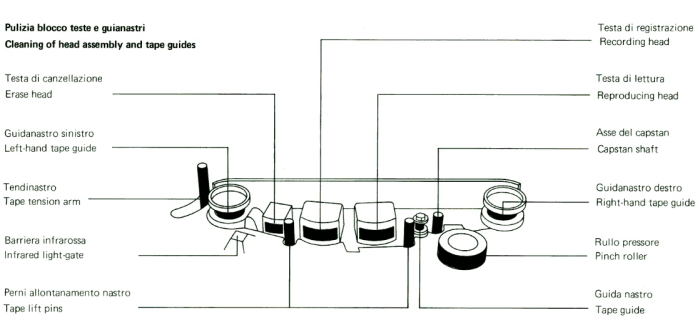

The picture below, from a Revox owner's manual, shows in black the parts need periodical cleaning. Usually you can reach them in easy way without dismounting any part of the recorder than the heads cover.

When clean the parts.

REPLACE PINCH ROLLER.

- When in playback or record mode you ear high "hiss" level, lower playback volume than usual, unbalanced output level, loss of high frequency response, check up the heads: if they their surface is dirty by brown oxide dust deposit is time for cleaning.

How clean

the parts.

-

At first: turn the tape recorder off and pull the main plug out.

-

BEWARE: AVOID USING ANY METALLIC TOOL ! Heads work within mils tolerance and every scratch on their surface can compromise their right operation.

-

Use a "Cotton-fioc" with some drops of isopropyl or denatured alcohol on. Clean all the metallic surface only (not the rubber pinch roller) until they are shining and perfectly cleaned. Change the "Cotton-fioc" often.

-

Be sure none cotton little hair rests on the heads surface and other recorder parts.

-

Be sure none alcohol drop falls into the capstan ball bearing or bush to avoid damage it.

-

Clean the rubber pinch roller using a cleaning soft cloth with water and neutral soap until its surface looks black (or gray) and mat instead of brown and bright.

-

Avoid water falls into the shaft bearing and soap remains on the rubber surface at the end of cleaning.

-

Wait the alcohol and other liquids are completely dry before turn the power on.

-

Finish !

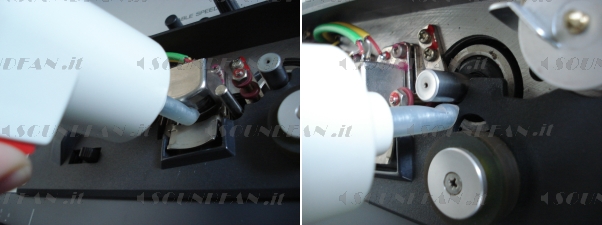

REPLACE PINCH ROLLER.

This

is another servicing you can do by yourself in many reel to reel

recorders (but not in everyones).

When replace it.

When replace it.

- When the rubber pinch roller surface looks bright and rigid as a glaze instead of mat and soft; or changed its colors; or it is sticky; or has visible damages; or is egg shaped instead of perfectly round.

- When listening to continuous high frequency sounds you ear a frequency fluctuation in many times you have a pinch roller problem causing speed variation.

Old pinch roller with

bright and The same one

brand new

rigid surface. |

Deformed contact surface

|

Detached rubber part |

Melted rubber |

How replace it.

-

The method can be different from a tape recorder to another one. Usually the pinch roller is set in its position by a screw and a washer. Using a non magnetized tool you can unscrew the screw to remove and change the pinch roller. Be careful avoid to touch the heads with the metallic screwer. At last don't forget the very thin washer, if present, when mounting the new pinch roller.

DEMAGNETIZING

This

is a very important procedure because a tape recorder with

magnetized parts can damage or destroy a pre recorded tape.

You

have to degauss all the metallic parts in contact with the magnetic

tape with special care to the heads.

Don't abuse of this procedure but use when strictly necessary.

You need a device called "demagnetizer" (or "degausser") which generates a strong magnetic filed in opposite to the magnetic field affects the metallic parts. This is why you must pay attention using this device to avoid the adverse. There are still many "vintage" devices on the used marked today but not everyone is good enough and do the same work. AVOID all that have about the size of a big Cuban cigar and Sony Head Demagnetizer HE-4, Nakamichi Head Demagnetizer DM-10, Radio Shack models 44-211 and 44-207, MCM Tape Head Demagnetizer Model 720880 and so on. They could work for cassette deck but are not strong enough for reel machines.

Don't abuse of this procedure but use when strictly necessary.

When you

have to do it.

-

After a good cleaning if you still ear high level hiss or background noise or have poor quality recording

-

Before use again a recorder turned off for many time

-

Before a master recording or listening to rare and precious tapes

-

Before using alignment tapes.

-

Every 20 hours about of use

You need a device called "demagnetizer" (or "degausser") which generates a strong magnetic filed in opposite to the magnetic field affects the metallic parts. This is why you must pay attention using this device to avoid the adverse. There are still many "vintage" devices on the used marked today but not everyone is good enough and do the same work. AVOID all that have about the size of a big Cuban cigar and Sony Head Demagnetizer HE-4, Nakamichi Head Demagnetizer DM-10, Radio Shack models 44-211 and 44-207, MCM Tape Head Demagnetizer Model 720880 and so on. They could work for cassette deck but are not strong enough for reel machines.

My "vintage" but great working Ferrograph demagnetizer |

-

Be calm and patient: if today you are blue or nervous go jogging around and will demagnetize the next day! :-))

-

Demagnetizers usually are not for continuous work and have a on-off duty cycle. Read the instruction of your model.

-

Turn the recorder and demagnetizer off.

-

Turn the demagnetizer on FAR AWAY from the recorder heads as possible, SLOWLY approach the parts and stay on them for about 3/5 seconds with no jerky motion.

-

Pass from one heads to another one (erase, record and playback) at VERY SLOW speed (and I mean VERY SLOW now i.e. 1" every 3 seconds) with no jerky motion.

-

BEWARE: avoid to touch or hit the heads surface.

-

At the end bring the demagnetizer away SLOWLY from the recorder and turn it off far away as possible, back to your original starting point.

-

Finish !

Demagnetizer at work on heads

and on capstan shaft

|

WHAT YOU CAN'T DO BY

YOURSELF

Although you

are not a

professional in electronic please read the following: you will find

other interesting news.Unless

you are a professional or semi professional in electronic with a well

equipped laboratory the servicing you can do by yourself on a

tape recorder stops at the last paragraph. If your reel to reel

recorder doesn't work just fine after the above

ordinary maintenance call an official servicing center

or a qualified electronic laboratory.

! BEWARE!

Avoid

absolutely to handle the heads and tape guide calibration screws!

Usually they don't need any modification from their original setting.

If you change their position don't think bringing them

back resolve the situation. At this point you need an

expensive full alignment of the recorder by a qualified

servicing

center. The main thing in reel to reel recorder is the perfect mechanical contact of tape with magnetic heads surface. It has to be perfect to have a clear and high level output signal. The electronic circuits downstream have less importance than the upstream right mechanical aspect. This is why BEFORE any electronic alignment they have to check the right tape path, tension and speed, the brakes and heads azimuth and zenith angles.

Often this fact is underrated. On the market you will find many seller claiming the recorder is electronic perfectly aligned, but none words about mechanical! :-(

What to check. They can find on the market two reel to reel recorders same model, firm and aged: one is looking as brand new and the other one as taken out from a garbage dump! And good looking doesn't necessary mean best working.

Always I do these check step by step:

-

BEFORE turn the recorder on I check its outside general condition, the wear and dirty of the external parts, tape guides, heads, pinch roller, check the fuse, the main plug and cord integrity and the right main voltage setting.

-

Next step I dismantle the recorder and check the inside general condition looking for burned components, the original lacquer drops on the calibration screw and the . . . dust! Dust can tell you much about the device. An equally spread dust means all the parts are original and the recorder is not a tweaked machine. I never trust in vintage device with none dust inside unless they said me the recorder has been recently cleaned and aligned and give me under warranty.

-

Only when the previous check are O.K. I turn the recorder on, check the power supply voltages, transport tape, playback and record functions, and the absence of noise from the input, output and monitor switches.

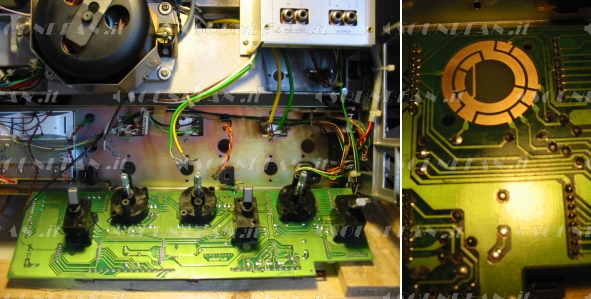

What to do. It depends on the different problems I found before.

-

If none big trouble occurred I just clean the recorder outside (and believe me some times this could be very hard . . .) to bring it back nice looking, clean the inside, demagnetize, check the mechanical and electronic alignment as per servicing booklet.

-

Lubrication is not necessary for all tape recorders but only if required by the factory. I.e. Revox, Studer and Telefunken reel to reel recorders don't need lubrication. Oil could be dangerous if non requested.

-

The most common electronic faults usually are due to dirty switches, calibration trimmers (i.e. in older Revox machine they have to be always replaced), electrolytic and tantalum faulty caps and at last transistor or i.c. when you have background noise or distortion problems.

-

Regarding the mechanical usually the parts to replace are bearings, brakes parts and rubber parts when present (belt, pulley, transfer, etc.).

I.e.: to have a Revox B77

input and monitor rotary switches W E L L

cleaned is not enough a cleaning spray but it needs to completely

dismantle the recorder to remove the switches from p.c. board.

|

Rubber

parts as

belt, pulley, transfer, etc. are the Achille's heel of every electronic

vintage device. Every people in love with old turntable as Garrard,

Thorens and EMT, knows very well the problem. Year passing by the

rubber part self destroy especially if in contact with lubricate oil

of the mechanical parts. These rubber part usually today are not

disposable. Many good reel to reel recorders which could still work

today are stopped due to a 10 dollars rubber part missing. This is why

I love Revox,

Studer and Telefunken recorders: they are bullet proof built

with none rubber part inside!

To repair

and/or align every electronic device you need the servicing book. Is

not simply today find these booklets for vintage device. Ebay

and

the web can help you but if you are searching something "special" it

will take many time to find it around.

All rights reserved. © 2007 - 2015 Cesare Marchesini. Legal statement, sources, contents reproduction: please refer to the home page